CURA Adjust-A-Web

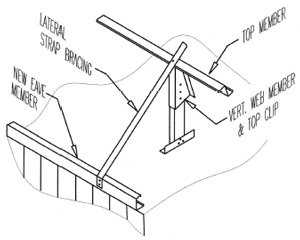

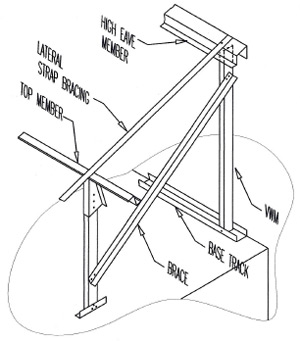

Typical Eave Condition

The Eave Member (EM) is typically a cold formed shape made from a minimum of 16 Ga. 55 KSI steel. It is normally fastened to the edge of the existing structure at the best structural location. Various configurations are available to best adapt the new system to existing conditions.

The Lateral Strap Bracing (S 1) IS typically 24 Ga. continuous strap and is fastened to the Eave ~ember. It runs continuous from the eave over the ridge and is fastened to the Eave Member on the far side. It passes over the ridge at the Top Clip connections to the ridge Top Member, Sl 's are normally spaced at the same spacing as the Vertical Web Members, but the spacing is determined by the design requirements of the specific project.

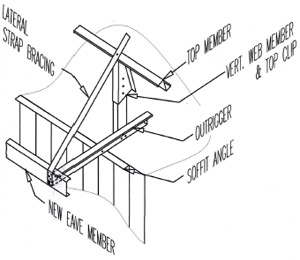

CURAAdjust-A-Web Eave Condition with Overhang

CURAAdjust-A-Web Eave Condition with Overhang

Outrigger (OR) is typically a roll-formed ZEE or CEE shape made from a minimum of 16 Ga. 55.~SI steel. And is used to position a new eave past the edge of the existing structure.

Continuous Soffit Angle (SA) is typically a rollformed 14 Ga. angle and is used when required, to provide a fastenable surface for the new color trim and panels.

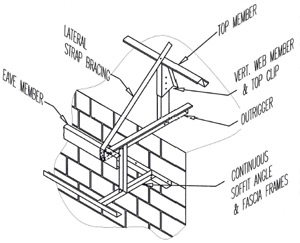

CURAAdjust-A-Web Eave Condition with Fascia & Soffit Framing Many variations are possible when fascia & soffit framing is required.

Fascia & Soffit framing is typically made from roll-formed 16 Ga. CEE's and ZEE's and 14 Ga. angle.

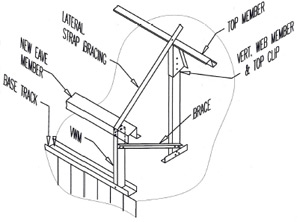

CURA Adjust-A-Web Eave Condition with Low Ponywall

Ponywall Eaves are used to provide an extended eave wall.

CURAAdjust-A-Web Eave Condition with High Side Ponywall

Used when a half ridge is required on a single sloped roof.

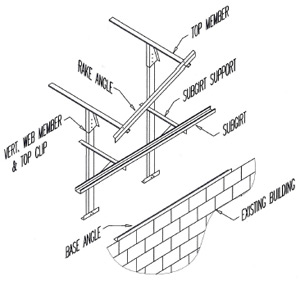

CURA Adjust-A-Web Typical gable condition

Base Angle (BA), Subgirt (SG) and Rake Angle (RA) are positioned at the edge of the roof to provide a fastenable surface to support the new wall panels.

Subgirt is typically made of 16 Ga. ZEE or CEE and the Base Angle, Rake Angle & Subgirt Supports (SS) are typically made from 14 Ga. angle.