Suggested Fastener Guidelines

See ReRoof America, Inc. 's (RRA) project specific drawings for Retrofit Roof Framing

System fastening details and specifications.

RRA and their consultants do not investigate the adequacy of the existing structure to

withstand the loads transmitted and imposed by the new roof and the Retrofit Roof

Framing System. Connections of the roof panel to the new framing system and of the

new framing system to the existing structure shall be designed and provided by others

unless specific arrangements have been made with RRA to provide this service.

General Information

The first step in determining what fastener to use in attaching to the existing structure is

to determine what the existing structural members are, the direction they run (if

applicable), and the spacing of the members. These members are typically going to be

steel (such as beams or bar joists), concrete (such as structural concrete slabs, hollow core

planks, double tees, waffle pan deck), or wood (such as wood beams or joists). If the

new bottom member is going to rest on the existing roofmg material, which is frequently

done, it is also important to know the thickness and make up of these materials. This will

help to determine the required fastener length and whether or not a particular fastener will

be appropriate. The thickness should be checked in more than one location since it can

vary due to things like tapered insulation systems or partial roof repairs.

Fastener selection should be made in conjunction with someone who is knowledgeable

about fasteners. RRA can provide assistance with this, as can most fastener suppliers.

Making a good fastener selection requires at least the following information.

• Composition and thickness of existing structural element to be attached to.

• Composition and thickness of existing materials to be penetrated between the new system bottom member and existing structural member.

• Design loads that the fastener must resist.

• The ease or difficulty of locating the existing structural members.

Fastener selection can be done based on either pullout tests or manufacturers published

pullout ratings for their fasteners in various materials. These values will be dependent on

the strength of the base material and either the thickness of this material or the depth of

embedment of the fastener. The more doubt that exists about the existing material, the

more prudent it is to conduct an actual test. In general, steel is very predictable if it is in

good condition. Concrete or wood is less so because there is a much wider variation in

the strength of these materials. Concrete or wood that has experienced long term

exposure to trapped moisture should almost certainly be tested because of the

deteriorating affects that this can have on the strength of these materials.

Pullout tests and manufacturer's pullout tables will typically provide an ultimate pullout

value. This is the load at which the connection fails. In choosing a fastener a safety

factor must be applied to this ultimate value. Safety factors that are widely used are 3 for

a single fastener connection into steel, 2.25 for a multiple fastener connection into steel,

and 4 for any connection into either wood or concrete. The ultimate load value must be

divided by this safety factor to determine the design load that the connection will safely

resist.

The following information is compiled from numerous product manufacturers literature and should be used as a guide only. Job site conditions should be taken into consideration when determining the proper fasteners and this is a responsibility of the installer or specifier. RRA assumes no liability for the use of this information.

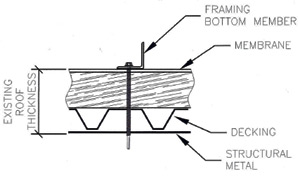

1. Connections to METAL type structural material.

- A. Examine the existing roof and structural condition.

The new roof system bottom members must be attached to the existing structural

member(s).

Pull out tests should be performed to help determine roof condition and fastener

type. Contact your local fastener supplier for assistance.

Penetrations caused by pull out tests must be sealed to prevent leaks prior to

installation of the new roof.

Analyze existing roof to assure that the pull out, deflection and dead loads

associated with the new roof can be met. Refer to RRA's specific job design load

criteria and attachment

requirements for

magnitude of loads

transmitted to the existing

structure.

Analyze existing roof to assure that the pull out, deflection and dead loads

associated with the new roof can be met. Refer to RRA's specific job design load

criteria and attachment

requirements for

magnitude of loads

transmitted to the existing

structure.

It is recommended that the existing structural member be a minimum of 16 gauge to accept the new roof load requirements.

Examine the existing roof to determine roof condition and appropriate fastening method. If there is any doubt regarding the integrity of the existing roofing membrane and insulation the existing materials should be compression tested to assure that the new roof system can be supported.

- B. Determine fastener requirements.

Thread length must be a minimum of 5/8" longer than the existing roof thickness.

Point type of self drilling fasteners are determined by structural member thickness.

Fastener strength should meet or exceed load requirements.

It is recommended that a minimum size of # 12 diameter fasteners be used to keep

fastener quantities and membrane penetrations to a minimum.

Fasteners should be supplied with long-life coatings or be of stainless steel material for added corrosion protection. Existing roofing materials should be evaluated for any corrosive affects they might have on a particular type of fastener.

Contact your local fastener supplier or RRA for assistance in defining the proper

mechanical, physical and material properties.

C. Installation Hints.

Locate existing structural members and prepare roof surface to accept the base design of the new framing system.

Apply sealant between existing roof and the underside of framing bottom members, particularly at attachment locations to provide temporarily watertightness.

Install fasteners perpendicular to roof surface. Drill point failure can occur during installation if threads tap before drilling is completed.

Cover fastener with sealant to prevent leaks.

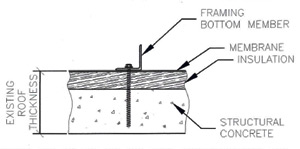

2. Connections to CONCRETE type structural material.

- A. Examine the existing roof and structural condition.

The new roof system bottom members must be attached to the existing structural concrete with a minimum embedment as required to attain the desired strength.

Pull out tests should be performed to help determine roof condition and fastener type. Contact your local fastener supplier for assistance.

Pull out tests should be performed to help determine roof condition and fastener type. Contact your local fastener supplier for assistance.

Penetrations caused by pull out tests must be sealed to prevent leaks prior to installation of the new roof.

Analyze existing roof to assure that the bearing, pullout, and shear loads associated with the new roof can be adequately supported. Refer to RRA's specific job design load criteria and attachment requirements for magnitude of loads transmitted to the existing structure.

Examine the existing roof to determine roof condition and appropriate fastening method. If there is any doubt regarding the integrity of the existing roofing membrane and insulation, the existing materials should be compression tested to assure that the new roof system can be supported.

- B. Determine fastener requirements.

The appropriate fastener can be a Threaded Anchor, Drive Anchor, Wedge Anchor or an Epoxy Anchor.

Choose anchor length based on membrane and insulation thickness, and the required embedment in the concrete.

Fastener strength should meet or exceed load requirements.

It is recommended that a minimum size of W' diameter fasteners be used to keep fastener quantities and membrane penetrations to a minimum.

Fasteners should be supplied with long-life coatings or be of stainless steel material for added corrosion protection. Existing roofmg materials should be evaluated for any corrosive affect they might have on a particular type of fastener.

Contact your local fastener supplier or RRA for assistance in defining the proper mechanical, physical and material properties.

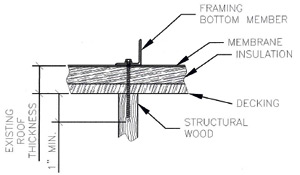

3. Connections to WOOD type structural material.

-

A. Examine the existing roof and structural condition.

The new roof system bottom members must be attached to the existing wood structure.

Pull out tests should be performed to help determine roof condition and fastener type. Contact your FRAMING local fastener BOTTOM MElviBER supplier for assistance.

Pull out tests should be performed to help determine roof condition and fastener type. Contact your FRAMING local fastener BOTTOM MElviBER supplier for assistance.

Penetrations caused by pull out tests must be sealed to prevent leaks prior to installation of the new roof.

Analyze existing roof to assure that the pullout and shear loads associated with the new roof can be adequately supported. Refer to RRA's specific job design load criteria and attachment requirements for magnitude of loads transmitted to the existing structure.

It is recommended that the existing wood structure be capable of 1" minimum fastener embedment to accept the new roof load requirements.

Examine the existing roof to determine roof condition and appropriate fastening method. If there is any doubt regarding the integrity of the existing roofing membrane and insulation the existing materials should be compression tested to assure that the new roof system can be supported. -

B. Determine fastener requirements.

Choose fastener diameter based on expected minimum pull out results.

Fastener strength should meet or exceed load requirements.

Fasteners should be supplied with long-life coatings or be of stainless steel material for added corrosion protection. Existing roofing materials should be evaluated for any corrosive affect they might have on a particular type of fastener.

Contact your local fastener supplier or RRA for assistance in defining the proper mechanical, physical and material properties. -

C. Installation Hints.

Locate existing wood structure and prepare roof surface to accept the base design of the new framing system.

Apply sealant between existing roof and the underside of framing bottom members, particularly at attachment locations to provide temporary watertightness.

Install fasteners so that a minimum of 1" of embedment or as otherwise specified by attachment designer is achieved.

Cover fastener with sealant to prevent leaks.